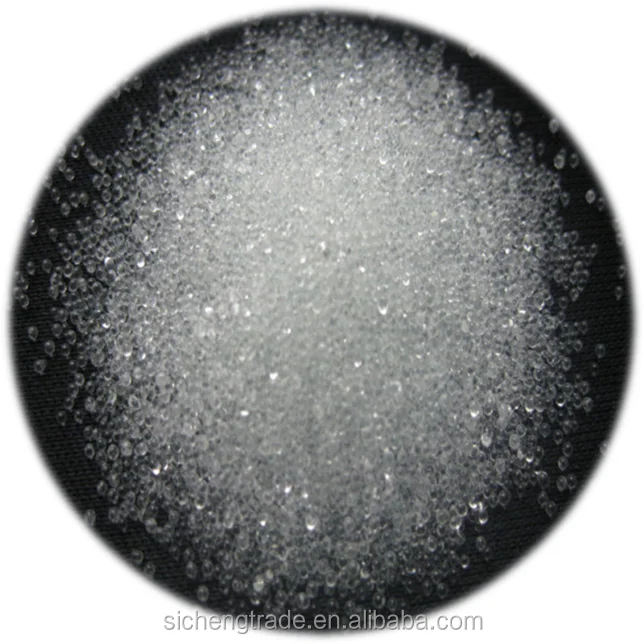

11mm tolerance 0.3mm glass beads for Making Wine bottle Cap

1.Product Description

The glass microbead production line USES the principle of the flame floating method to break the recycled waste glass into particles of certain size and send the glass particles into the flame in a certain way. Under the action of the flame, the glass particles become glass beads by softening, melting, beading, cooling and curing. Appearance glass beads clean, transparent, no obvious bubble and impurities.

2.Chemical and physical parameters

Glass Beads | |||||||||

Shape | Round | Color | Colorless Transparent | ||||||

Mohs Hardness | 6-7 | HRC hardness | 46 | ||||||

Real Density | 2.5g/cm3 | Bulk Density | 1.5g/cm3 | ||||||

Si02 | 70.2% | Na20 | 12.5% | ||||||

Ca0 | 9.0% | Mg0 | 3.6% | ||||||

Al203 | 3.8% | Fe203 | 0.1% | ||||||

3.Packaging & Delivery

Packaging Details:

a) 25 kg pvc bag + 1 Metric Ton bag or 1 Metric Ton bag

b) 25kg pvc bag + 1 Metric Ton pallet

Delivery Time:

Shipped in 7 -10 days after payment

4.Size

Sandblasting | 20-30# 30-40# 40-50# 50-70# 60-80# 70-100# 80-120# 100-170# 120-200# 140-230# 170-325# |

Grinding | 0.8-1mm 1-1.5mm 1.5-2mm 2-2.5mm 2.5-3mm 3.5-4mm 4-4.5mm 4-5mm 5-6mm 6-7mm 8mm 9mm 10mm 11mm 12mm 13mm 14mm 15mm 16mm |

Road Marking | BS6088A BS6088B EN1424 EN1423 AASHTO TYPE1 AASHTO TYPEII JIS NO.1 2 |

5.Applications

1, Bead hit aviation parts, eliminate its stress, in order to increase fatigue strength, and reduce friction and wear;

2. Industrial sand blasting

3. Grinding medium

4. Stuffed toys and handicrafts

5. Road marking

Customer visit